VT-X700-E / -L

High-speed automated X-ray CT inspection system

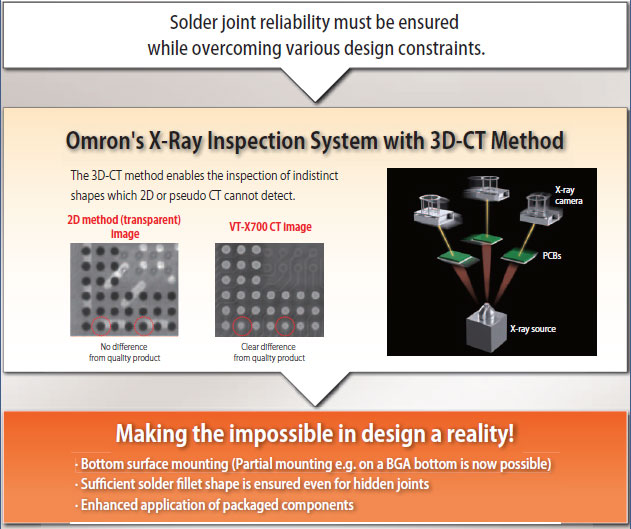

The 3D-CT method enables the inspection of indistinct shapes which 2D or pseudo CT cannot detect. Making the impossible in design a reality!

* Information in this page is a reference that you created on the basis of information in the product catalog before the end of production, may be different from the current situation, such as goods for / supported standards options / price / features of the product. Before using, please check the compatibility and safety system.

last update: January 6, 2016

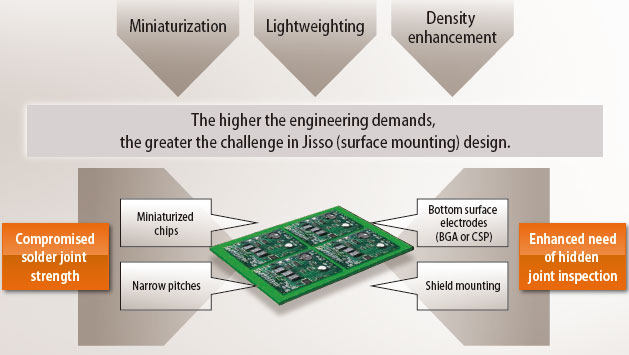

Market Trends and Issues

Pinpoint Inspection

3D-CT Method

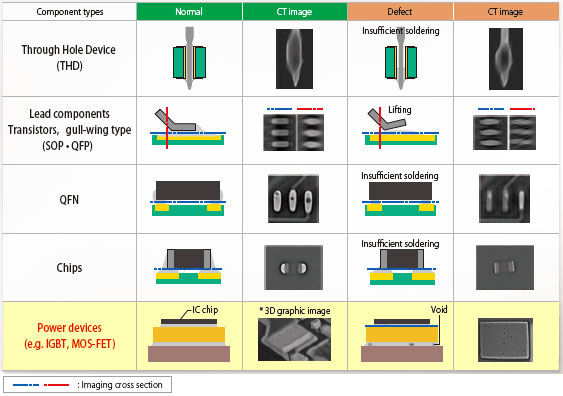

The cross-sectional images of relevant inspection targets can be easily selected from abundant camera-image libraries to ensure precise fault detection.

Full coverage

High-Output X-Ray Source

Inspection of large-thickness PCBs and power devices is possible by combining a proprietary CT structuring technology with a high-output X-ray source.

Compatibility with L-Sized (610 mm × 610 mm) PCBs

Compatible with large-sized PCBs such as those used by network base stations.

High-speed

10% Reduction in Inspection Tact Time (Internal Comparison)

World's highest CT speed* thanks to our patent-approved technologies.

New imaging system reduced inspection tact times by 10% compared with conventional systems.

Enabled the complete inspection of all components

(almost impossible by visible light-based inspection).

* Based on an internal research conducted in January 2015.

last update: January 6, 2016

Product Category

Product Category

Power Supplies / In Addition

Power Supplies / In Addition

-

Inspection System

Inspection System

-

Discontinued

- VT-X700-E / -L

-

Discontinued

-