TM S Series

OMRON TM Collaborative Robot, S Series

S Series Collaborative Robot (Cobot) for assembly, palletizing, inspection, logistics and many other applications

last update: October 15, 2024

OMRON TM Collaborative Robot - S Series

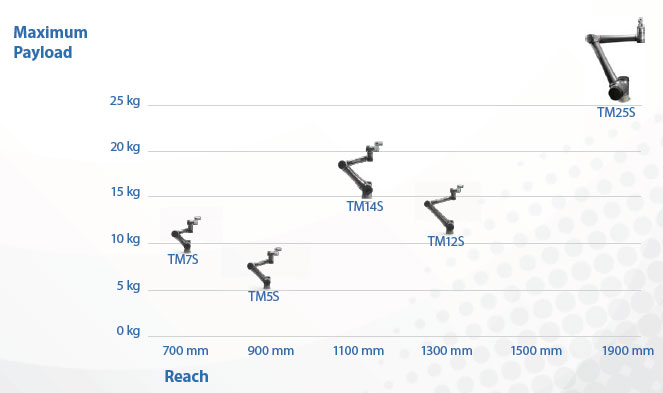

The OMRON TM Collaborative Robot - S Series includes a wide variety of models with reach and payload suitable for different applications, including the DC power mobile robot compatible, EtherNet/IP, and PROFINET versions.

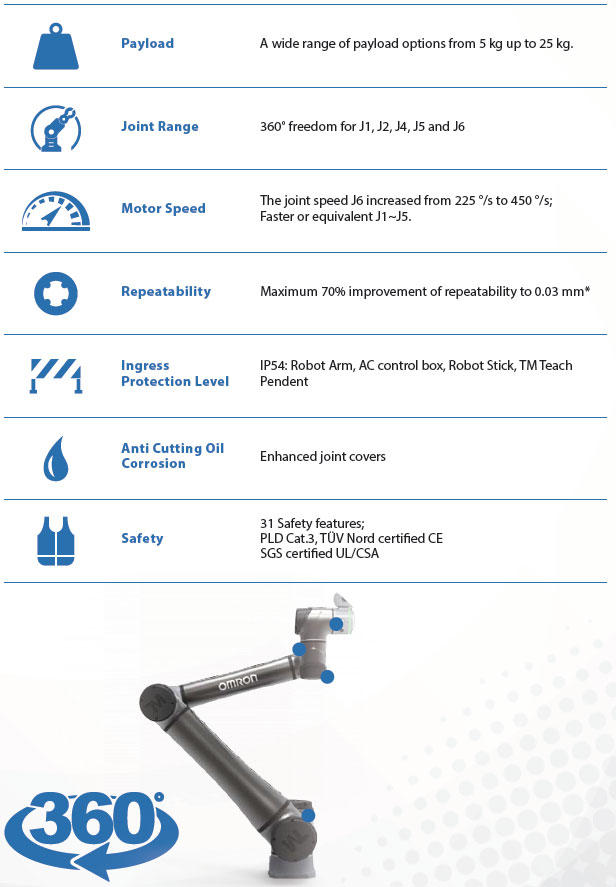

With 31 Safety Features, the OMRON S Series meets ISO 13849-1, Cat.3, PL D and ISO 10218 -1 Safety Standards, certified by TUV Nord. The new OMRON S Series also comes with the UL/CSA certifications from SGS.

Target Industries

OMRON TM Collaborative Robots are designed for a wide variety of applications in a number of industries.

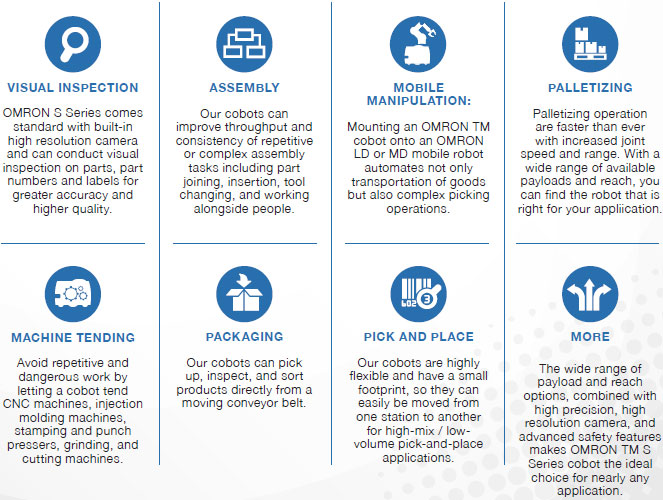

Target Applications

Ease of use

Improved hand guidance and next-generation teach pendant make programming the OMRON S Series easier than ever.

Advanced hand guiding experience:

Applications can be programmed using the built-in hand guidance function. Simply move the head to the desired position, and with the click of a button, the position is taught.

The new Robot Stick is designed to convert an OMRON TM Screen to a teaching pendant.

• Operate, control, and program the cobot using a touch screen

• No wiring or additional chip installation required

• OMRON TM Pen comes standard with the OMRON TM S Series Cobots

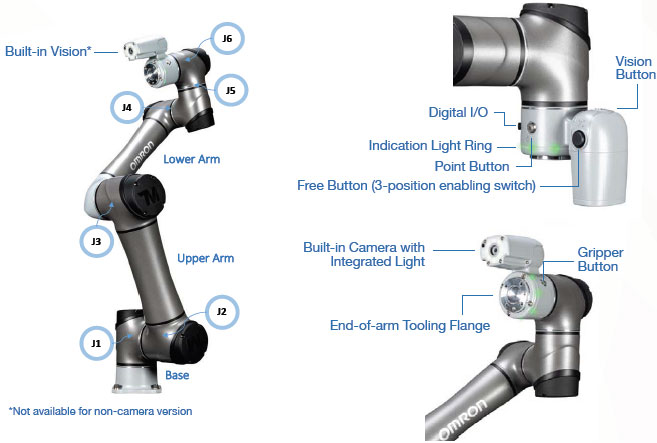

Built-In Vision System

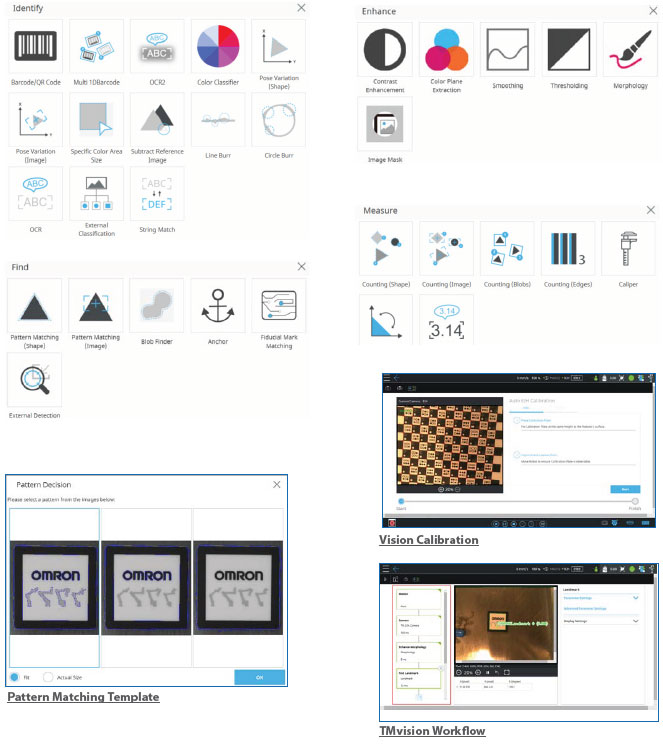

The integrated vision system is the biggest advantage of OMRON TM cobots. It is designed for industrial grade pattern recognition, object positioning, and feature identification. Users can set up vision tasks for immediate deployment without going through complex steps if integrating external cameras or lighting equipment.

Ease of use

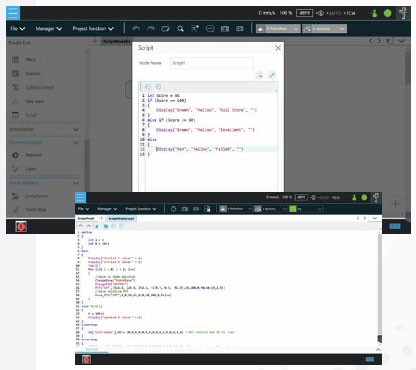

The OMRON S series collaborative robots are easy to use and can be programmed using a variety of methods, including hand guidance, flow-chart programming or manual scripting.

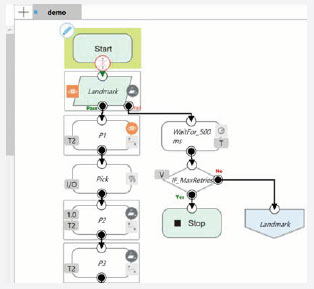

Graphical Programming

Our innovative programming allows users to automate a task with flow-based software, creating full workflows with a click-and-drag method in TMFlow. Via Operator Platform, building an application software layout is very intuitive by drag and drop visual elements, no need for trial and error via complex coding.

Omron Next Generation Cobot – Faster Programming

The script programming method in both Project and Mode, will be available for S. The Script language may enable the advanced users to program Cobot projects more concise and organized.

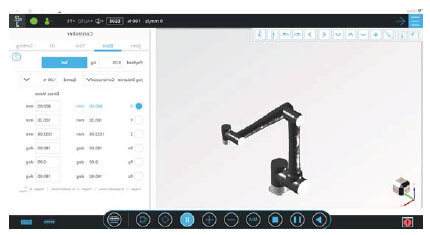

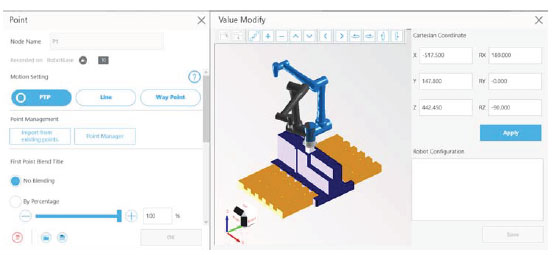

TMSimulator

The new OMRON TMSimulator lets users test and verify proper operation by developing, editing and running programs offline. By building programs offline, users can develop new processes without having to take a robot out of production.

The onscreen display includes a virtual robot stick so users can control the robot just as they would control a physical robot. In addition to the standard robot control buttons, the virtual robot stick has buttons for RESET, Point, and Gripper.

The TMSimulator can test Listen Node and Network Node communications. Modbus, Ethernet Slave, and serial configurations can also be tested.

The TMSimulator also has options for DI and AI Signal Control Box Input Control.

This version of TMSimulator works with the following S Series Model robots (HW5.0):

•TM5S-X

•TM7S-X

•TM12S-X

•TM14S-X

•TM25S-X

TMflow

OMRON’s highly versatile programming software for collaborative robots is more capable and easier to use than ever before.

Programming Improvements

Project Stop and Error Stop Handling Procedures

•Users can create special subflow logic to define the steps the robot takes after a project or error stop.

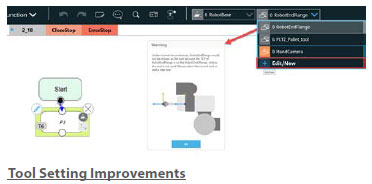

Tool Setting Improvements

•Tool Settings option added to the project page for easier access so users no longer need to navigate away from the project page to change Tool Settings.

Operational Improvements Behavior

Improvements when Passing Through

•The new Singularity Handling feature imroves the robot’s behavior by purposefully slowing down at the point of singularity and avoiding joint speed errors and sudden stops. This feature can be enabled for Point and Move nodes that use Line motions. Motion blending will be disabled when Singularity Handling is enabled.

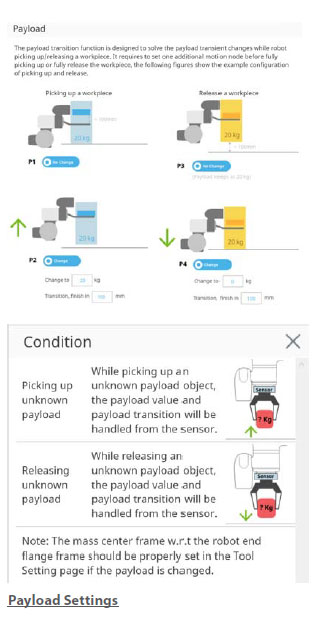

Redefine Payload Settings in Motion Nodes

•New Payload Settings UI in motion nodes make it easier for users to configure the robot picking up or releasing a workpiece. For applications with unknowno or widly varying payloads, the robot can now use an external for and torque sensor to automatically calculate and compensate for the payload mass.

Pattern-Matching UI Improvement

•Users can choose from three pattern-matching algorithms in TMvision Find tasks for more reliable results. The object detection score is more intuitive, represented as a single numerical value.

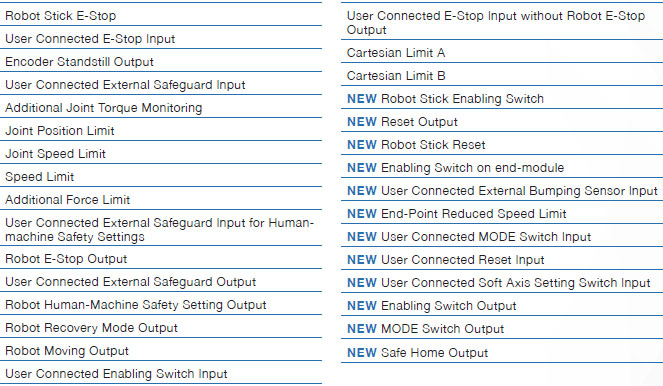

Safety

Newly added safety functions provides for a wide variety of safety devices/switch configurations without the need for an additional safety controller.

Safety Features

• 31 Safety features in total

• 12 Newly added safety features

Certifications:

• ISO 13849-1, Cat.3, PL d

• ISO 10218-1:2011

• UL & CSA Safety Certification

Protections:

• IP54 rating for Robot Arm, AC control box, Robot Stick and TM screen.

• ISO Class 3 for the Cleanroom

• Enhance oil resistant covers for joints

Anatomy of OMRON TM S Series Cobot

OMRON S Series Cobots’ Main Advantage

Cobots vs. Industrial Robots

OMRON TM Collaborative Robots change the way in which traditional factories work.

Physical cages are no longer needed. Designed for high-mix, low-volume production at a speed comparable to human workers, OMRON cobots can work in harmony with humans.

Plug & Play

OMRON has partnered with a select number of companies to offer a wide variety of peripherals that quickly and easily integrate with our cobots, allowing for a faster deployment and return on investment. They are collectively referred to as Plug & Play devices and software, designed to serve a broad range of customer applications and meet the highest testing standards of OMRON.

Plug & Play Kits

All products come as a ready-to-use kit for easy installation

last update: October 15, 2024