VT-X750

High-speed automated X-ray CT inspection system

In-line Full Inspection System

last update: July 11, 2022

VT-X750 Case Study

The X750 is used for non-destructive inspection of 5G infrastructure/modules and in-vehicle electrical components as a high-definition, high-quality inspection using full 3D-CT. In recent years, the VT-X750 has been used for inspection of solder voids and solder filling of through-hole connectors in final assembly of power devices such as IGBTs and MOSFETs, which are essential for EVs, as well as Integrated machine and electric power. It has also been widely utilized in the fields of aerospace, industrial equipment, and semiconductors.

In-line full inspection coverage [Omron Patent]

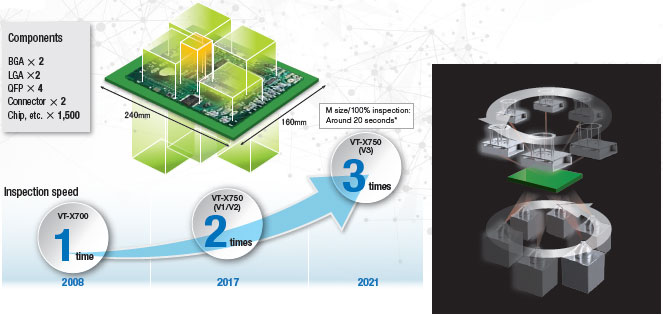

The VT-X750 improves upon previous Omron 3D-CT technology making it the fastest X-Ray inspection system to date *¹.

The automated inspection logic has been improved for many parts such as IC heal fillets, stacked devices (PoP), through hole components, press-fit connectors, and other bottom terminated parts.

Increasing automated inspection speed and expanding inspection logic enables full, in-line inspection coverage by 3D-CT method.

*1. By an internal investigation in October, 2021.

sides of board including 2 pieces BGA which has 2,000 to 3,000 pins, or SiP.

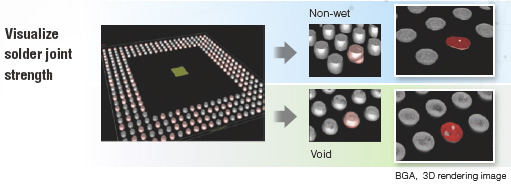

Visualize solder joint strength

OMRON’s unique 3D-CT reconstruction algorithms provide excellent solder shape recognition and defect detection.

Quantitative analysis allows for an automated inspection process which minimizes the risk of escapes while providing fast and repeatable operation.

Design constraint free

Dense and dual sided board design can provide challenges for X-Ray inspection.

However, Omron's 3D-CT technology can overcome such design restraints.

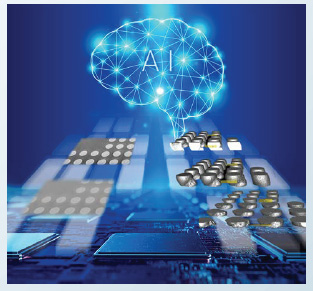

Criteria setting by Auto-Judge reduces the dependency on a dedicated programmer [Patent Pending]

This dynamic approach enables a comprehensive analysis using Omron AI with quantitative decision making based on conventional inspection standards for OK / NG judgment.

(3D cross-sectional display functionality has been integrated into the screen, making the inspection criteria settings easier to understand.)

Faster creation of new programs [Omron Patent]

Omron AI assists in the quick creation of new programs. Along with automated program generation using CAD data, Omron AI automatically tunes the parts library using inspection result data.

Accelerated simulation for Patent Pending production preparation [Omron Patent]

Omron AI simulates the optimum tact and exposure dosage for each part and automatically determines the corresponding conditions for the X-ray inspection process.

* Simulation pertains to specific parts.

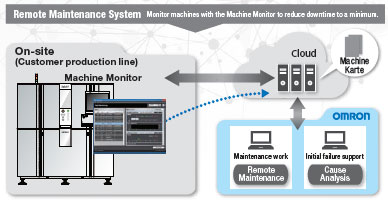

Zero down time

To achieve “Never stop the production line = Zero downtime”, OMRON provides global support for customer operations with a full range of maintenance services, including machine monitoring for predictive maintenance and remote access for emergency support.

Reduction of product radiation exposure

High speed and low radiation imaging technology

A filter that reduces the effects of radiation exposure has been installed as standard, and concerns about radiation exposure, especially to memory components, have been minimized by realizing high-speed imaging.

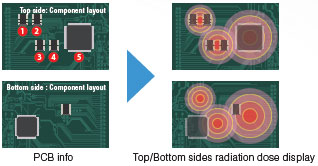

Parts radiation exposure simulator [Omron Patent]

The exposure of each component on the top side and bottom side of PCB can be simulated with high accuracy.

last update: July 11, 2022